AMS ASME ASTM maka inconel625 alloy navigators

AMS ASME ASTM maka inconel625 alloy navigators,

625 Alloy, Inconel 625 Ogwe, Inconel 625 mkpanaka, Inconel 625 mpempe akwụkwọ, Inconel 625 efere, Inconel 625 warara, Inconel 625 eriri igwe,

Aha Azụmahịa nkịtị: Inconel 625, UNS NO6625, Nickel Alloy 625, Alloy 625, Nickel 625, W.Nr.2,4856

Inconel Alloy 625 bụ ihe na-abụghị magnetik, corrosion na oxidation eguzogide, nickel-chromium alloy.Ike dị elu nke Inconel 625 bụ nsonaazụ nchikota nke molybdenum na niobium siri ike na ntọala nickel chromium nke alloy.Inconel 625 nwere nnukwu nguzogide n'ebe dị iche iche na-emebi emebi na-adịghị ahụkebe gụnyere mmetụta dị elu dị ka oxidation na carburization.Ike ya pụtara ìhè na ike ya na ọnọdụ okpomọkụ sitere na okpomọkụ cryogenic ruo n'ogo dị elu ruo 2000 ° F (1093 ° C) bụ nke sitere na ngwọta siri ike nke metal refractory Columbium na molybdenum na nickel-chromium matrix.

Inconel 625 Chemical mejupụtara

| % | Ni | Cr | Fe | Mo | Nb+Ta | Co | C | Mn | Si | S | Al | Ti | P |

| Min. | 58.0 | 20.0 | - | 8.0 | 3.15 | - | - | - | - | - | - | - | - |

| Oke. | - | 23.0 | 5.0 | 10.0 | 4.15 | 1.0 | 0.1 | 0.5 | 0.5 | 0.015 | 0.4 | 0.4 | 0.015 |

Inconel 625 Njirimara anụ ahụ

| Njupụta | 8.4g/cm³ |

| Ebe mgbaze | 1290-1350 ℃

|

Inconel 625 Njirimara arụrụ arụ

| Ọnọdụ | Ike ọdụdọ Rm N/mm² | Mpụta ike Rp 0. 2N/mm² | Ogologo oge Dị ka% | Brinell siri ike HB |

| Ọgwụgwọ ọgwụgwọ | 827 | 414 | 30 | ≤220 |

Inconel 625 Ụkpụrụ na nkọwapụta

AMS 5599, AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3,073-NACE

UNS N06625, Werkstoff 2.4856

| Waya | Mpempe akwụkwọ | Mwepu | Mkpanaka | Ọkụ | |

| AMS 5599, AMS 5666, AMS 5837, AMS 5979, ASTM B443 | ASTM B443 | AMS 5599, AMS 5979, ASTM B443 | ASTM B 446 SAE/AMS 5666, VdTÜV 499 | Pipe enweghị nkebi | Ọkpọkpọ welded |

| ASTM B 444/B 829 & ASME SB 444/SB 829SAE/AMS 5581 | ASTM B704/B751 ASME SB704/SB 751ASTM B705/B 775 , ASME SB 705/SB 775 | ||||

Ngwa inconel 625 dị na Sekonic Metals

Inconel 625 Ogwe & mkpanaka

Ogwe okirikiri / Ogwe Flat / Hex Ogwe, Size Si 8.0mm-320mm, Eji maka bolts, fastners na akụkụ ndị ọzọ mapụtara

Inconel 625 ịgbado ọkụ waya

Na-eweta na ịgbado ọkụ waya na mmiri waya na eriri igwe ụdị na bee ogologo.

Inconel 625 mpempe akwụkwọ & efere

Obosara ruo 1500mm na ogologo ruo 6000mm, ọkpụrụkpụ si 0.1mm ka 100mm.

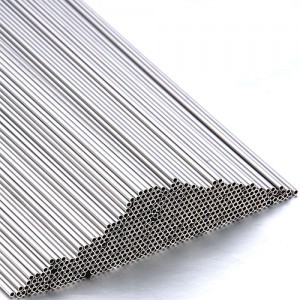

Inconel 625 enweghị nkebi tube & Welded ọkpọkọ

Ụkpụrụ nha na nha ahaziri iche nwere ike ịmepụta site na anyị na obere ntachi obi

Inconel 625 eriri & eriri igwe

Ọnọdụ dị nro na ọnọdụ siri ike na elu AB na-egbuke egbuke, obosara ruru 1000mm

Inconel 625 fasteners

Alloy 625 anyị nwere ike na-enye bolts, mkpụrụ na ndị ọzọ fasteners dị ka ahịa chọrọ

Njirimara Inconel 625:

1.High creep-rupture ike

2.Oxidation na-eguzogide 1800 ° F

3.Good ike ọgwụgwụ na-eguzogide

4.Excelent weldability

5.outstanding iguzogide chloride pitting na crevice corrosion

6.Immune ka chloride ion stress corrosion cracking

7.Resistant na mmiri mmiri n'okpuru ma na-asọpụta na ọnọdụ na-adịghị mma na n'okpuru mmebi

Inconel 625 Ngwa:

•Sistemụ ducting ụgbọ elu

•Sistemụ iyuzucha ụgbọ elu

•Sistemụ ihe ngbanwe nke igwe

•Bellows na nkwonkwo mgbasawanye

•Turbine shroud yiri mgbaaka

•Ọkụ ọkụ

•Akụkụ mmiri mmiri

•Ngwa usoro kemịkalụ na-ejikwa acid agwakọtara ma oxidizing na ibelata.

Ụdị ngwaahịa ụlọ ọrụ anyị

Ogwe & mkpanaka

Inconel / Hastelloy/ Monel/ Haynes 25/ Titanium

tube na-enweghị ntụpọ & welded tube

Nickel / Titanium Alloy tubes, U-ehulata / okpomọkụ mgbanwe tube

Bolt & Akụ

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Mpempe akwụkwọ & efere

Hastelloy/Inconel/ Incoloy/Cobalt/Tianium

Mwepu & foil

Hastelloy/Inconel/invar/ soft magnetik Alloys ect

Mmiri dị elu

Inconel 718/Inconel x750/Nimonic 80A

Waya & ịgbado ọkụ

Cobalt Alloy waya, Nickel alloy waya,Tianium Alloy waya

Ọpụrụiche Alloy Flanges

Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

Oil Tube Hanger

Inconel x750/ Inconel 718 /Monel 400 ect

Alloys dabeere na nickel

Ngwa ịgbado ọkụ

Alloys dabere na Cobalt

Igwe anaghị agba nchara Pụrụiche

Alloys nkenke

Titanium Alloys

Chọrọ ịmụtakwu ma ọ bụ nweta nkwuputa?

Nweta kọntaktị

Kedu ihe bụ 625 alloy mere?Alloy dabere na nickel nwere Ni – Cr – Mo dị elu.

Chemical mejupụtara nke Alloy 625: Chromium (Cr) 20.0-23.0, Iron (Fe) < 5.0, (Al) & lt;0.4, Silicon (Si) <0.50 manganese (Mn)< 0.50, Nickel (Ni) 258, sọlfọ (S)< 0.015, Cobalt (Co) < 1.0, (Mo) 8.0-10.0, Titanium (Ti)< 0.4, Phosphorus (P) <0.015, (Nb) 3.15-4.15, Carbon (C) <0.01.

625 Alloy na-egosipụta ọmarịcha oxidation na nguzogide corrosion, ike dị mma na ike siri ike, nguzogide ike ọgwụgwụ dị mma, ụdị dị elu, yana weldability mara mma.Ọ nwere ike idowe ike ya na ike ya ebe ọ bụla site na obere okpomọkụ ruo 2000 ° F.N'ihi ike siri ike nke alloy 625 ngwa ngwa, oke oyi na-akpụ nwere ike ịchọ ịkachasị ahụ n'oge usoro ịkpụ oyi.A na-ejikarị alloy eme ihe na igwe jet na ngwa ikuku ndị ọzọ.