Haynes25 elu okpomọkụ na-eguzogide alloy

Haynes25 alloy na-eguzogide okpomọkụ dị elu,

Haynes25 mejupụtara, L605, arụmọrụ, R30605,

Azụmahịa nkịtị: Haynes 25, AlloyL605, Cobalt L605,GH5605, Udimet L605, UNSR30605

Haynes 25 (AlloyL605) bụ ihe ngwọta siri ike na-ewusi cobalt-chromium-tungsten nickel alloy na ike dị elu nke okpomọkụ na ezigbo nguzogide oxidation na 2000 ° F (1093 ° C).Alloy ahụ na-enyekwa ezigbo nguzogide sulfidation na iguzogide iyi na galling.Alloy L-605 bara uru na ngwa turbine gas dị ka mgbanaka, agụba na akụkụ ụlọ combustion (ichepụta mpempe akwụkwọ) yana enwere ike iji ya na ngwa ọkụ ụlọ ọrụ dị ka muffles ma ọ bụ liners na nnukwu okpomọkụ kilns.

Haynes 25(Alloy L605) Ngwakọta kemịkalụ

| C | Cr | Ni | Fe | W | Co | Mn | Si | S | P |

| 0.05-0.15 | 19.0-21.0 | 9.0-11.0 | ≦3.0 | 14.0-16.0 | itule | 1.0-2.0 | ≦0.4 | ≦0.03 | ≦0.04 |

Haynes 25(Alloy L605) Njirimara anụ ahụ

| Njupụta (g/cm3) | Ebe mgbaze (℃) | Kpọmkwem ike okpomọkụ (J/kg·℃) | Eletriki resistivity (Ω·cm) | Thermal conductivity (W/m·℃) |

| 9.27 | 1300-1410 | 385 | 88.6 × 10E-6 | 9.4 |

Haynes 25(Alloy L605) Ihe eji arụ ọrụ

Ihe nnochite anya Tensile, Mpempe akwụkwọ

| Okpomọkụ, °F | 70 | 1200 | 1400 | 1600 | 1800 |

| Ike tensile kacha elu, ksi | 146 | 108 | 93 | 60 | 34 |

| 0.2% Ike Mpụta, ksi | 69 | 48 | 41 | 36 | 18 |

| Mgbatị, % | 51 | 60 | 42 | 45 | 32 |

Ihe mgbakasị ahụ a na-ahụkarị - ike mgbawa

| Okpomọkụ, °F | 1200 | 1400 | 1500 | 1600 | 1700 | 1800 |

| 100 Awa, ksi | 69 | 36 | 25 | 18 | 12 | 7 |

| 1,000 Awa, ksi | 57 | 26 | 18 | 12 | 7 | 4 |

Haynes 25(Alloy L605) Ụkpụrụ na nkọwapụta

AMS 5537, AMS 5796, EN 2.4964, GE B50A460, UNSR30605Ụlọ ọrụ 2.4964

| Ogwe/Ogwe | Waya/welding | Eriri / eriri igwe | Mpempe akwụkwọ/efere | Pipe/Tube |

| AMS 5537 | AMS 5796/5797 | AMS 5537 | AMS 5537 | - |

Haynes 25(Alloy L605) Ngwaahịa dị na Sekonic Metals

Alloy L605 Ogwe & mkpanaka

Ogwe okirikiri / Ogwe Flat / Hex Ogwe, Size Si 8.0mm-320mm, Eji maka bolts, fastners na akụkụ ndị ọzọ mapụtara

Alloy L605 ịgbado ọkụ waya

Na-eweta na ịgbado ọkụ waya na mmiri waya na eriri igwe ụdị na bee ogologo.

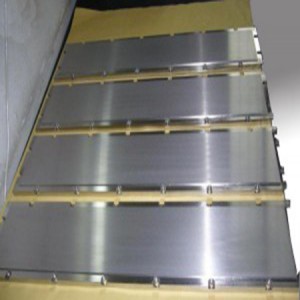

Alloy L605 mpempe akwụkwọ & efere

Obosara ruo 1500mm na ogologo ruo 6000mm, ọkpụrụkpụ si 0.1mm ka 100mm.

Alloy L605 Gasket / mgbanaka

Enwere ike ịhazi akụkụ ya site na iji elu na-egbuke egbuke na nnabata ziri ezi.

Alloy L605 eriri & eriri igwe

Ọnọdụ dị nro na ọnọdụ siri ike na elu AB na-egbuke egbuke, obosara ruru 1000mm

Kedu ihe kpatara Inconel Haynes 25 (Alloy L605)?

•Ike okpomọkụ dị elu pụtara ìhè

•Oxidation na-eguzogide 1800°F

•Na-eguzogide ọgwụ galling

•Na-eguzogide gburugburu mmiri, acids na mmiri ara

Haynes 25(Alloy L605) ubi ngwa:

•Ngwa igwe turbine gas dị ka ụlọ ọkụ na ihe ndị na-ekpo ọkụ

•Bọọlụ okpomọkụ dị elu na asọmpi ibu

•Mmiri

•Ọkpụkpụ obi

Haynes 25 alloy bụ cobalt-nickel-cr-w alloy na - elu okpomọkụ ike na -1800 ° F (980 ° C) oxidation gburugburu ebe obibi, ogologo ikpughe, na - vulcanization resistance.It nwere ike arụpụtara na kpụrụ site ot usoro na nwere. ejiri mee ihe maka nkedo akụkụ. Ihe ndị ọzọ na-adọrọ adọrọ na-agụnye iguzogide iyi na ịkwa akwa na ọla. Ụdị ngwaahịa dị: A na-emepụta ihe n'ụdị efere, mpempe akwụkwọ, ibe, billlets, mkpanaka, wires, electrodes mkpuchi, tubes na tubes. Nkọwa ngwaahịa. : Haynes 25 Alloy ka aha ya bụ R30605.Ogwe, Ogwe, Waya na Forgings: AMS 5759 (ogwe, mgbanaka na forgings), Ibé akwụkwọ, mpempe akwụkwọ na ibe: AMS 5537 (Ibé akwụkwọ, ibe na mpempe akwụkwọ) Ndị ọzọ: AMS 5796 (Way) na AMS 5797 (electrodes ịgbado ọkụ mkpuchi)