Mmiri mmiri dị elu nke mmiri mmiri mmiri mmiri

Mmiri dị elu:

Mmiri bụ akụkụ arụ ọrụ nke na-eji elasticity arụ ọrụ.Akụkụ nke ihe eji eme ihe na-agbanwe agbanwe n'okpuru ọrụ nke ike mpụga, ma laghachi na ọdịdị mbụ ha mgbe ha wepụsịrị ike mpụga.A na-ejikwa ya dị ka "mmiri".Na-emekarị nke mmiri ígwè.Ụdị isi iyi dị mgbagwoju anya ma dị iche iche.

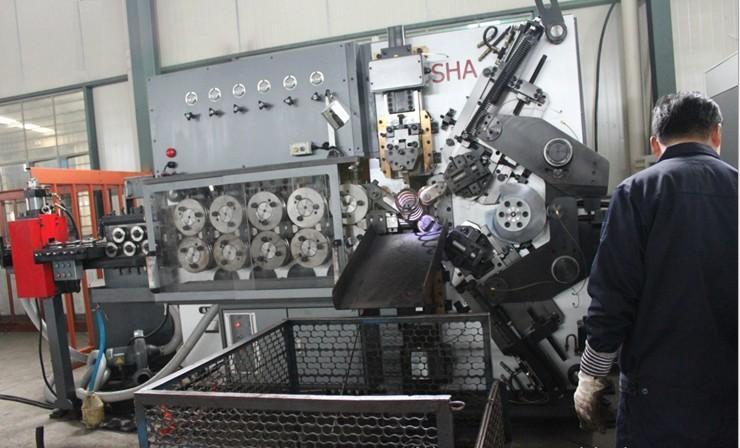

Companylọ ọrụ anyị United nwere ụlọ ọrụ ndị ọkachamara n'oge opupu ihe ubi na-emepụta ma na-ebunye isi mmiri dị elu

• Igwe mmiri dị elu nke mmiri mmiri:

SUS304,SUS316, SUS631/17-7PH, SUS632/15-7Mo, 50CrVA, 30W4Cr2VA,

Inconel X-750, Ọnụ ego nke 718, Nimonic90, Incoloy A286(SUH660)

• Ụdị mmiri:

→Mkpakọ mmiri → Mgbatị mmiri

→Torsion Spring → Na-ehulata mmiri

♦ Mmiri mmiri mmiri ♦ PịgharịaMmiri♦ Disc Spring

♦ Mgbanaka mmiri ♦ Mmiri pụrụ iche, wdg

| Ụdị ihe onwunwe | Aha ihe | Okpomọkụ Ngwa kachaCelsius C |

| igwe anaghị agba nchara | SUS304/SUS316 | 200 |

| SUS631/17-7PH | 370 | |

| SUS632/15-7Mo | 470 | |

| Alloy mmiri ígwè | 50CrVA | 300 |

| 30W4Cr2VA | 500 | |

| Okpomọkụ dị elu nickel base alloy | Incoloy A286(GH2132) | 600 |

| Inconel X-750 (GH4145) | 600 | |

| Inconel 718 (GH4169) | 690 | |

| Nimonic90 (GH4090) | 800 (γ<0.2) | |

| GH4099 | 1000 (γ<0.1) |

♦♦♦ Disc Springs♦♦♦

A na-ejikarị ha na valves, flanges, clutches, brakes, torque converters, High-voltage switch, bolt tightening, pipeline support, shockproof and shockproof ubi.ha mepụtara dị ka DIN EN16983 (DIN2093).

Dayameta nke mpụta sitere na 6mm ruo 1000mm.

Ngwa gụnyerealloy ígwè 51CrV4, carbon ígwè SK85, 1074;

• igwe anaghị agba nchara ASTM301, 304, 316, 17-7PH, 17-4PH, 15-7Mo;

• ígwè na-eguzogide ọkụ H13, X30WCrV53, X22CrMoV12-1, X39CrMo17-1;

• Igwe anaghị agba nchara dị elu na-eguzogide okpomọkụ Inconel X750, Inconel X718, Nimonic 90, wdg.

♦♦♦ Mmiri mmiri♦♦♦

Mmiri ebili mmiri bụ ihe mgbanaka na-agbanwe dị mkpa nke nwere ọtụtụ crests na ndagwurugwu.A na-eji isi iyi ebili mmiri na moto, igwe textile, akụrụngwa hydraulic, ụgbọ ala na ụlọ ọrụ ndị ọzọ.Isi ntinye na nkọwapụta (ọnụọgụ ọnụ) nke ọnụ ụlọ na-ebu kwesịrị ekwesị.Ma ọ bụ na oghere, oghere ntinye dị ntakịrị, ọ nwekwara ọrụ pụrụ iche nke ibelata mkpọtụ na ibelata mkpọtụ.

Dayameta nke mpụta sitere na 6mm ruo 1000mm.ọkpụrụkpụ sitere na 0.4mm ruo 5.0mm.

Nchedo ajari

- Phosphate

- Mechanical galvanizing

- Nickel gbazere

- Jiaomei

Ha nwere njirimara nke obere nrụrụ na nnukwu ibu.Ọ nwekwara atụmatụ ndị a.

- Isi iyi diski nwere ike nweta njirimara ibu dị iche iche site na nchikota dị iche iche nke ntụgharị na ndakota.

- Tụnyere isi iyi ndị ọzọ, isi iyi diski na-ewe obere ohere.

- Mgbe a na-eji ọtụtụ mpempe akwụkwọ na-ejikọta, mmetụta na-ekpo ọkụ na-abawanye.

- Mgbe ejiri ya mee ihe nke ọma, ọ gaghị agbawa ma ọ bụ gbajie.

- Ogologo ndụ ike ọgwụgwụ.

| Ngwa mmiri mmiri | Okpomọkụ ọrụ | Ike ọdụdọ | Ihe na-agbanwe Modulus KN//mm2 | Chemistry% | ||||||||||||||||||

| Celsius C | N/mm2 | RT°C | 100°C | 200°C | 300°C | 400°C | 500°C | 600°C | C | Si | Mn | P | S | Cr | Ni | Ndị ọzọ | ||||||

| T8A SK85 | -50 ruo +100 | 1200-1800 | 206 | 202 | - | - | - | - | - | 0.80-0.09 | ≤ 0.35 | ≤ 0.50 | ≤ 0.03 | ≤ 0.03 | ≤ 0.20 | ≤ 0.25 | Cu≤0.30 | |||||

| 50CrV4 SUP10 | -50 ruo +200 | 1200-1800 | 206 | 202 | 196 | - | - | - | - | 0.47-0.55 | ≤ 0.4 | 0.71.1 | ≤ 0.025 | 0.025 | 0.9 1.2 | ≤ 0.4 | V: 0.1 0.25Mo≤ 0.1 | |||||

| C75 | -50 ruo +100 | 1200-1800 | 206 | 202 | - | - | - | - | - | 0.70-0.80 | 0.15-0.35 | 0,60 0,90 | ≤ 0.025 | 0.025 | ≤ 0.4 | ≤ 0.4 | Mo≤ 0.1 | |||||

| 60Si2Mn SUP6 | -50 ruo +200 | 1200-1800 | 206 | 202 | 196 | - | - | - | - | 0.56-0.64 | 1.50-2.0 | 0.60.9 | 0.035 | 0,035 | ≤ 0.35 | ≤ 0.35 | ||||||

| X 10CrNi 18-8 SUS301 | -200 ruo +200 | 1150-1500 | 190 | 186 | 180 | - | - | - | - | 0.05-0.15 | ≤ 2.0 | ≤ 2.0 | 0.045 | 0.015 | 16.0 19.0 | 6.0 9.5 | Mo≤ 0.08 | |||||

| X 5CrNi 18-10SUS304 | -200 ruo +200 | 1000-1500 | 185 | 179 | 171 | - | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 2.0 | 0.045 | 0.015 | 17.0 19.5 | 6.0 9.5 | N≤ 0.11 | |||||

| X 5CrNiMo 17-12-2 SUS316 | -200 ruo +200 | 1000-1500 | 180 | 176 | 171 | - | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 2.0 | 0.045 | 0.015 | 16.5-18.5 | 10.0 13.0 | Mo: 2.0-2.5N≤ 0.11 | |||||

| X 7CrNiAl 17-7 SUS631 | -200 ruo +300 | 1150-1700 | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.09 | ≤0.7 | ≤ 1.0 | ≤ 0.04 | 0.015 | 16.0 18.0 | 6.5 7.8 | Al: 0.7-1.5 | |||||

| X5CrNiCuNb 16-4 SUS630 | -200 ruo +300 | 1150-1700 | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 1.0 | 0.035 | 0.03 | 15.0 17.0 | 3.0 5.0 | ||||||

| X8CrNiMoAl 15-7-2 | -200 ruo +300 | 1150-1700 | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.09 | ≤ 1.0 | ≤ 1.0 | ≤ 0.04 | 0.03 | 14.0 16.0 | 6.5 7.75 | Mo:2.0-3.0Al: 0.75-1.5 | |||||

| Igwe igwe X39CrMo 17-1 | -50 ruo +400 | 1200-1400 | 215 | 212 | 205 | 200 | 190 | - | - | 0.33-0.45 | ≤ 1.0 | ≤1.5 | ≤ 0.04 | 0.03 | 15.5 17.5 | ≤ 1.0 | Mo: 0.7-1.3 | |||||

| X 22CrMoV 12-1 | -50 ruo +500 | 1200-1400 | 216 | 209 | 200 | 190 | 179 | 167 | - | 0.18-0.24 | ≤0.5 | 0.4 0.9 | ≤ 0.025 | 0.015 | 11 12.5 | 0.3-0.8 | V: 0.25-0.35Mo: 0.8-1.2 | |||||

| X30WCrV53 SKD4 | -50 ruo +500 | 1470 | 216 | 209 | 200 | 190 | 179 | 167 | - | 0.25-0.35 | 0.15-0.30 | 0,20 0,40 | 0.035 | 0,035 | 2.2 2.5 | ≤ 0.35 | V: 0.5-0.7 W: 4-5 | |||||

| X40CrMoV5-1 SKD61 | -150 ruo +600 | 1650-1990 | 206 | 200 | 196 | 189 | 186 | 158 | - | 0,32 0,40 | 0.8 1.20 | 0,20 0,50 | ≤ 0.030 | 0,030 | 4.75 5.50 | V: 0.80-1.20Mo: 1.1-.75 | ||||||

| Nickel Inconel X750 | -200 ruo +600 | 1170 | 214 | 207 | 198 | 190 | 179 | 170 | 158 | ≤ 0.08 | ≤ 0.50 | ≤ 1.0 | ≤ 0.02 | 0.015 | 14.0 17.0 | ≥ 70 | Co≤ 1.0 Ti2.25-2.75 Fe 5.0-9.0 | |||||

| Inconel X718 | -200 ruo +600 | 1240 | 199 | 195 | 190 | 185 | 179 | 174 | 167 | 0.02 0.08 | ≤ 0.35 | ≤ 0.35 | ≤ 0.015 | 0.015 | 17.0 21.0 | 50.0 55.0 | V≤ 1.0Mo: 0.70-1.15 | |||||

| Nimonic 90 | -200 ruo +700 | ≥ 1100 | 220 | 216 | 208 | 202 | 193 | 187 | 178 | ≤ 0.13 | ≤ 1.0 | ≤ 1.0 | ≤ 0.03 | 0.015 | 18.0 21.0 | Bal | V15.0-21.0Mo: 2.0-3.0 Al≤ 0.2 | |||||

♦♦♦ Igwe mmiri dị elu Njirimara Njirimara: ♦♦♦

♦ 304 igwe anaghị agba nchara

Igwe anaghị agba nchara 304 na-emebi site na ịrụ ọrụ oyi iji melite njirimara ya.Enweghị ike imesi ya ike site na ọgwụgwọ okpomọkụ.Ọ ga-emepụta magnetism n'oge ọrụ oyi.Igwe anaghị agba nchara 304 nwere nguzogide corrosion siri ike yana ezigbo anụ ahụ.

316 igwe anaghị agba nchara na-emebi site na oyi na-atụ na-arụ ọrụ iji meziwanye ihe na-agbanwe ya, ọ nweghịkwa ike ime ka ọ sie ike site na ọgwụgwọ okpomọkụ.Ọ ga-emepụta magnetism n'oge ọrụ oyi.Igwe anaghị agba nchara 316 nwere molybdenum, nke nwere nguzogide corrosion siri ike karịa igwe anaghị agba nchara 304, ma nwee ike iguzogide corrosion na ngwa kemịkalụ.

17-7PH yiri nke corrosion eguzogide 304 igwe anaghị agba nchara, nke nwere ike precipitated site okpomọkụ ọgwụgwọ na ọdịda mmiri hardening.Ọ nwere nnukwu tensile na inye ike.Ọrụ ike ọgwụgwụ dị mma karịa igwe anaghị agba nchara 304 na 65Mn carbon steel.Ọ nwekwara ezigbo elasticity n'okpuru ℃ gburugburu ebe obibi.

♦15-7Mo (GH632, 0Cr15Ni7Mo2Al)

15-7MoHas yiri corrosion eguzogide 316 igwe anaghị agba nchara.Enwere ike ịmalite ya site na ọgwụgwọ okpomọkụ na mmiri ozuzo siri ike.Ọ nwere nnukwu tensile ma na-enye ike, na ike ọgwụgwụ ya dị mma karịa igwe anaghị agba nchara 316 na 65Mn carbon steel.Ọ nwekwara ezigbo elasticity n'okpuru ℃ gburugburu ebe obibi.

Inconel X-750 bụ mmiri ozuzo siri ike na-eme ka nrụrụ superalloy dabere na nickel.Ọ na-ejikarị r'phase dị ka oge mmiri ozuzo ịka nká na-emesi ike.Okpomọkụ akwadoro dị n'okpuru 540 ℃.Alloy ahụ nwere ụfọdụ nguzogide corrosion na oxidation, ma nwee ụfọdụ arụmọrụ dị ala dị ala.

Inconel 718 bụ mmiri ozuzo siri ike na-eme ka nrụrụ superalloy dabere na nickel.Oke okpomọkụ akwadoro bụ -253--600 ℃.Alloy nwere ike dị elu n'okpuru 600 Celsius C, nwere ezigbo ike ọgwụgwụ ike ọgwụgwụ, nkwụsị nke radieshon, oxidation resistance na corrosion resistance, yana ezigbo nhazi nhazi na nkwụsi ike nhazi ogologo oge.

Alloy A-286 bụ mmiri ozuzo dabere na ígwèn hardening deformation elu-okpomọkụ alloy.The atụ aro na-arụ ọrụ okpomọkụ dị n'okpuru 540 ℃.Alloy nwere elu dị elu na obere okpomọkụ ike na ogologo oge kwụsie ike, ezigbo corrosion eguzogide na thermal deformation arụmọrụ, na nwere ezi plasticity nhazi na afọ ịgbado ọkụ arụmọrụ.