Inconel X-750 corrosion na oxidation resistance na elu ike mmiri ozuzo hardening alloy

Inconel X-750 corrosion na ọxịdashọn nguzogide na elu ike mmiri ozuzo hardening alloy,

,

Aha ahia a na-ahụkarị: Alloy X750, Nickel X750,Nicrofer 7016, Superimphy 750, Haynes X750, Pyromet X750, na Udimet X750 UNS N07750 W.NR 2.4669

Inconel® X750 bụ nickel chromium alloy mere ka mmiri ozuzo sie ike site na mgbakwunye Titanium na aluminom.A na-eji ya mee ihe na akụkụ nhazi nke okpomọkụ dị elu dị ka QAS turbines, jet engine components, ngwa ngwa ọkụ ọkụ nuklia, ihe ndị na-ekpo ọkụ na-ekpo ọkụ, na-emepụta ngwá ọrụ na extrusion die.The alloy bụ nke ukwuu na-eguzogide ọgwụ corrosion na oxidation, na nwere nnukwu nrụgide ntachi obi ike. na ọnụ ọgụgụ dị ala na-akpụ akpụ na ọnọdụ nrụgide dị elu ruo 1500 ° F (816 ° C) mgbe ọgwụgwọ okpomọkụ kwesịrị ekwesị.Inconel X-750 nwere ike ịhazi ya site na iji usoro omenala maka ígwè dabeere na ígwè. Alloy a na-arụ ọrụ siri ike n'oge nhazi ma nwee ike dị elu na "Nrapara" karịa ụdị ígwè ndị a na-ahụkarị. Ekwesịrị iji ngwá ọrụ na-arụ ọrụ dị arọ na ngwá ọrụ iji belata flutter ma ọ bụ na-arụ ọrụ siri ike nke alloy tupu ịchachaa ngwá ọrụ ahụ. Ọ na-egosi na-eju afọ oxidation resistance na dị iche iche oxidizing environments.The alloy egosiputa yiri corrosion iguzogide alloy 600 na ọtụtụ mgbasa ozi.

Inconel X750 Chemical mejupụtara

| Alloy | % | Ni | Cr | Fe | Nb+Ta | Co | C | Mn | Si | S | Cu | Al | Ti |

| X750 | Min. | 70.0 | 14.0 | 5.0 | 0.7 | 0.4 | 2.25 | ||||||

| Oke. | - | 17.0 | 9.0 | 1.2 | 1.0 | 0.08 | 1.0 | 0.5 | 0.01 | 0.5 | 1.0 | 2.75 |

Inconel X750 Njirimara anụ ahụ

| Njupụta | 8.28g/cm³ |

| Ebe mgbaze | 1390-1430 ℃ |

Inconel X750 Njirimara arụrụ arụ

| Ọnọdụ | Ike ọdụdọ Rm N/mm² | Mpụta ike Rp 0. 2N/mm² | Ogologo oge Dị ka% | Brinell siri ike HB |

| Ọgwụgwọ ọgwụgwọ | 1267 | 868 | 25 | ≤400 |

Inconel X750 Ụkpụrụ na nkọwapụta

AMS 5667, AMS 5671, AMS 5698, AMS 5699, ASTM B637, BS HR 505, GE B14H41, ISO 15156-3 (NACE MR 0175)

| Waya | Mpempe akwụkwọ | Mwepu | Mkpanaka | Ọkụ |

| AMS5698 AMS 5699 | AMS5542 | AMS5542 | AMS 5667 AMS 5670AMS 5671 | AMS 5582 |

Ngwa Inconel X750 dị na Sekonic Metals

Inconel X 750 Ogwe & mkpanaka

Ogwe okirikiri / Ogwe Flat / Hex Ogwe, Size Si 8.0mm-320mm, Eji maka bolts, fastners na akụkụ ndị ọzọ mapụtara

Inconel X 750 waya ịgbado ọkụ

Na-eweta na ịgbado ọkụ waya na mmiri waya na eriri igwe ụdị na bee ogologo.

Inconel X-750 Heli-Coil

Enwere ike ịmepụta helicoil site n'aka anyị nabatara obere obere na nnyefe ngwa ngwa.

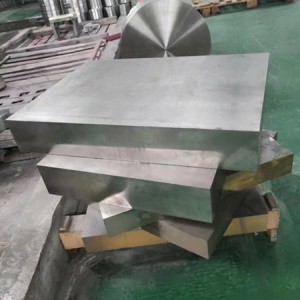

Inconel X 750 mpempe akwụkwọ & efere

Obosara ruo 1500mm na ogologo ruo 6000mm, ọkpụrụkpụ si 0.1mm ka 100mm.

Inconel X750 tube enweghị nkebi & ọkpọkọ welded

Ụkpụrụ nha na nha ahaziri iche nwere ike ịmepụta site na anyị na obere ntachi obi

Inconel X 750 mmiri

Mmiri nwere ụkpụrụ AMS5699 dịka eserese ma ọ bụ nkọwa ndị ahịa siri dị

Inconel X750 eriri & eriri igwe

Ọnọdụ dị nro na ọnọdụ siri ike na elu AB na-egbuke egbuke, obosara ruru 1000mm

Inconel X 750 fasteners

Alloy X 750 ihe n'ụdị bolts, kposara, flanges na ngwa ngwa ndị ọzọ, dị ka nkọwa ndị ahịa si dị.

Inconel X 750 Tubing Hanger

Enwere ike imepụta ya dabere na eserese ndị ahịa ma ọ bụ smaple nwere nnabata ziri ezi.

Njirimara Inconel X-750:

1.Good creep rupture ike na elu okpomọkụ

2.Ọ bụghị ike ka Nimonic 90

3.Ọ dị mma na okpomọkụ cryogenic

4.Age siri ike

5.High okpomọkụ ngwa ngwa

Inconel X-750 Ogige ngwa:

•Ihe nrụpụta nuklia

•Igwe ikuku gas

•Igwe rọketi

•Ụgbọ mmiri nrụgide

•Ọdịdị ụgbọ elu

Ụdị ngwaahịa ụlọ ọrụ anyị

Ogwe & mkpanaka

Inconel / Hastelloy/ Monel/ Haynes 25/ Titanium

tube na-enweghị ntụpọ & welded tube

Nickel / Titanium Alloy tubes, U-ehulata / okpomọkụ mgbanwe tube

Bolt & Akụ

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Mpempe akwụkwọ & efere

Hastelloy/Inconel/ Incoloy/Cobalt/Tianium

Mwepu & foil

Hastelloy/Inconel/invar/ soft magnetik Alloys ect

Mmiri dị elu

Inconel 718/Inconel x750/Nimonic 80A

Waya & ịgbado ọkụ

Cobalt Alloy waya, Nickel alloy waya,Tianium Alloy waya

Ọpụrụiche Alloy Flanges

Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

Oil Tube Hanger

Inconel x750/ Inconel 718 /Monel 400 ect

Alloys dabeere na nickel

Ngwa ịgbado ọkụ

Alloys dabere na Cobalt

Igwe anaghị agba nchara Pụrụiche

Alloys nkenke

Titanium Alloys

Chọrọ ịmụtakwu ma ọ bụ nweta nkwuputa?

Nweta kọntaktị

Ọkọlọtọ mmejuputa iwu: UNS, ASTM, AISI, DIN, GB/T14992, ụdị kwekọrọ: GB ọkọlọtọ ụdị GH4145, GH145, OCR15NI70TI3AINB, akara akara United States: INCONEL X-750, NO7750, German akara akara:2.46507.

Sekonic Metals Technology Co.Committed to special alloy research and development, n'ichepụta, ahịa nke X750, iji hụ na elu àgwà ntụpọ ọkọnọ nke X750 mpempe akwụkwọ, warara, mmanya, forging, annular, waya na ọkpọkọ., iche iche nkọwa, kwụsiri ike ọkọnọ, welcome to ndụmọdụ.