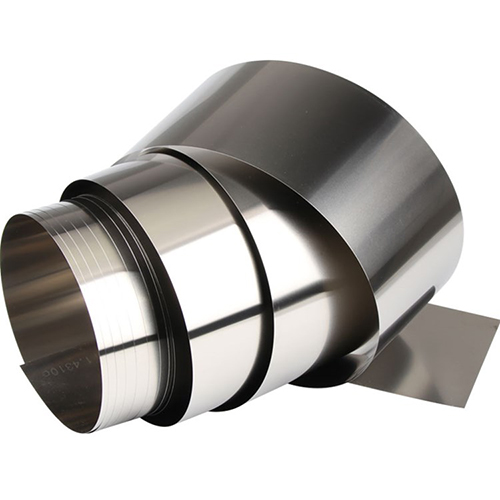

Titanium Strip na foil

• Tittanium Strip na Ngwa Ngwa:Titanium dị ọcha (CP) na Titanium alloy foil,Ọkwa 1, Ọkwa 2, Ọkwa 5, Ọkwa 5, Ọkwa 7 na Ọkwa 9

• Ụdị: Otu eriri, na eriri igwe, ma ọ bụ na spool.Ọrụ slitting dị

• Akụkụ:Ọkpụrụkpụ: ≥0.01mm: 20 ~ 1000mm, Ogologo: Dị ka Arịrịọ

• Ọnọdụ:Oyi akpọrepu (Y)~ akpọrepu ọkụ (R) ~ Annealed (M) ~ Ọnọdụ siri ike

• Ụkpụrụ:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 wdg.

• Ngwa:Eletrọnịkị, kemịkalụ, elekere, ugogbe anya, ọla, ngwa egwuregwu, igwe, akụrụngwa plattering, akụrụngwa gburugburu ebe obibi, gọlfụ na ụlọ ọrụ nrụpụta nkenke.

| Titanium Alloys Material Name | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Nke-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Nke-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Nke-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

Ihe mgbochi Titanium na foil:Anyị na-enyekarị titanium Strip nke Gr1, Gr2, Gr4 akara ule;N'ihi na titanium alloy foil, Anyị tumadi na-enye Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 na akara ule ndị ọzọ, Ha na-emepụta na ndabere nke titanium efere na n'ihu oyi Rolling;usoro mmepụta nke mpempe akwụkwọ titanium dị mgbagwoju anya karị.Njikwa nrụrụ na-esiwanye ike na usoro ntụgharị. Nke a nwere ike ịkpụ n'ụdị dị iche iche dị ka mkpa ndị ahịa si dị, na-ebelata oge nnyefe.

♦ Titanium Strip Chemical mejupụtara ♦

| Ọkwa | Ngwakọta kemịkalụ, pasentị arọ (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Ihe ndị ọzọ Oke.nke ọ bụla | Ihe ndị ọzọ Oke.ngụkọta | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.60.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum Alloy StripNjirimara anụ ahụ♦

| Ọkwa | Njirimara anụ ahụ | |||||||

| Ike ọdụdọ Min | Mpụta ikeNkeji (0.2%, akwụ ụgwọ) | Elongation na 4D Nkeji (%) | Mbelata Mpaghara Nkeji (%) | Nnwale Bend (Radius nke Mandrel) | ||||

| ksi | MPa | ksi | MPa | 1.8mm N'ọkpụkpụ | 1.8-4.8mm Na ọkpụrụkpụ | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 | 4.5T | 5.0T |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 | 2.0T | 2.5T |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 | 4.5T | 5.0T |

♦ ♦ ♦ Titanium Alloy Materials Atụmatụ: ♦ ♦ ♦

•Ọkwa 1: Titanium dị ọcha, ike dị obere na ductility dị elu.

•Ọkwa 2: titanium dị ọcha a na-ejikarị eme ihe.Ngwakọta kachasị mma nke ike

•Ọkwa 3: Titanium ike dị elu, ejiri maka Matrix-plates na shei na tube okpomọkụ

•Ọkwa 5: Alloy titanium kacha arụpụtara.Ike dị oke elu.nnukwu okpomọkụ na-eguzogide.

•Ọkwa 7: Nguzogide corrosion kacha elu na mbenata na gburugburu oxidizing.

•Ọkwa 9: Ike dị elu na nguzogide corrosion.

•Ọkwa 12: Nguzogide okpomọkụ ka mma karịa Titanium dị ọcha.Ngwa maka ọkwa 7 na ọkwa 11.

•Ọkwa 23: Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy maka ntinye ịwa ahụ.