Alloy Multimet N155 (AMS 5532 / AMS 5769)

Ndị ọrụ anyị site na ọzụzụ ọkachamara.Ọmụma nka ọkachamara, nghọta siri ike nke ọrụ, iji mezuo ihe ndị ahịa chọrọ maka AlloyMultimet N155(AMS 5532 / AMS 5769), Dị ka onye na-eduga n'ichepụta na onye na-ebupụ, anyị na-enwe obi ụtọ na ndekọ egwu dị egwu n'ime ahịa mba ụwa, karịsịa na America na Europe, n'ihi àgwà dị elu na ọnụ ahịa a na-anabata.

Ndị ọrụ anyị site na ọzụzụ ọkachamara.Ọmụma ọkachamara nwere nkà, nghọta siri ike nke ọrụ, iji mezuo ihe ndị ahịa chọrọAlloy N155, Multimet N155, UNS R30155, Biko na-eche na-eri-free iziga anyị gị nkọwa na anyị ga-aza gị ngwa ngwa.Anyị nwere otu ọkachamara injinia ga-eje ozi maka mkpa ọ bụla zuru ezu.Enwere ike izipu ihe nlele efu maka gị onwe gị ka ị mara eziokwu ndị ọzọ.Ka ị nwee ike mezuo ọchịchọ gị, biko nwee mmetụta na-efu efu iji kpọtụrụ anyị.Ị nwere ike izipu anyị email wee kpọọ anyị ozugbo.Ọzọkwa, anyị na-anabata nleta na ụlọ ọrụ anyị si n'akụkụ ụwa niile maka ịmatakwu ụlọ ọrụ anyị.nd ngwa ahia.N'ahịa anyị na ndị ahịa nke mba dị iche iche, anyị na-agbasokarị ụkpụrụ nke nha anya na uru otu.Ọ bụ olileanya anyị ịzụ ahịa, site na nkwonkwo mbọ, ma ahia na ọbụbụenyi ka anyị na-erite uru.Anyị na-atụ anya inweta ajụjụ gị.

Aha Azụmahịa nkịtị:Alloy N155, Multimet N155, R30155 , W.Nr 1.4974

Alloy N155bụ Nickel-Chromium-Cobalt alloy nwere mgbakwunye Molybdenum na Tungsten a na-ejikarị na akụkụ chọrọ ike dị elu ruo 1350ºF yana nguzogide oxidation ruo 1800°F.Ngwongwo okpomọkụ ya dị elu dị na ọnọdụ a na-enye ya (ngwọta a na-agwọ ya na 2150 ° F) na adabereghị na ịka nká.A na-eji Multimet N155 mee ihe n'ọtụtụ ngwa ikuku dị ka ọdụdụ ọdụ na cones ọdụ, turbine blades, shafts and rotors, afterburner components na elu okpomọkụ bolts.

Alloy N155 Chemical Composition

| Alloy | % | C | Si | Fe | Mn | P | S | Cr | Ni | Co | Mo | W | Nb | Cu | N |

| N155 | Min. | 0.08 | bal | 1.0 | 20.0 | 19.0 | 18.5 | 2.5 | 2.0 | 0.75 | 0.1 | ||||

| Oke. | 0.16 | 1.0 | 2.0 | 0.04 | 0.03 | 22.5 | 21.0 | 21.0 | 3.5 | 3.0 | 1.25 | 0.5 | 0.2 |

Alloy N155 Njirimara anụ ahụ

| Njupụta | 8.25 g/cm³ |

| Ebe mgbaze | 2450 ℃ |

Alloy N155 Mechanical Properties

| Ọnọdụ | Ike ọdụdọ Rm N/mm² | Mpụta ike Rp 0. 2N/mm² | Ogologo oge Dị ka% | Brinell siri ike HB |

| Ọgwụgwọ ọgwụgwọ | 690-965 | 345 | 20 | 82-92 |

Alloy N155 Ụkpụrụ na nkọwapụta

AMS 5532 , AMS 5769 , AMS 5794 , AMS 5795

| Ogwe/Rod Forging | Waya | Eriri / eriri igwe | Mpempe akwụkwọ/efere |

| AMS 5769 | AMS 5794 | AMS 5532 | AMS 5532 |

Alloy N155 Ngwaahịa dị na Sekonic Metals

Alloy N155 mmanya & mkpanaka

Ogwe okirikiri / Ogwe Flat / Hex Ogwe, Size Si 8.0mm-320mm, Eji maka bolts, fastners na akụkụ ndị ọzọ mapụtara

Alloy N155 welding waya & mmiri waya

Na-eweta na ịgbado ọkụ waya na mmiri waya na eriri igwe ụdị na bee ogologo.

Alloy N155 mpempe akwụkwọ & efere

Obosara ruo 1500mm na ogologo ruo 6000mm, ọkpụrụkpụ si 0.1mm ka 100mm.

Alloy N155 mgbanaka adịgboroja

Mgbanaka mgbanaka ma ọ bụ gasket, nha nwere ike ịhazi ya na elu na-egbuke egbuke na nnabata ziri ezi

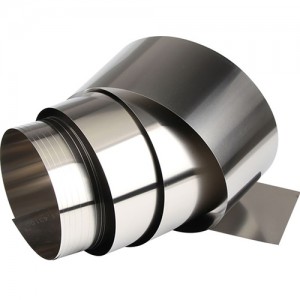

Alloy N155 strip & coil

Ọnọdụ dị nro na ọnọdụ siri ike na elu AB na-egbuke egbuke, obosara ruru 1000mm

Kedu ihe kpatara Alloy N155?

Alloy N155 nwere ezigbo nguzogide corrosion na ụfọdụ mgbasa ozi n'okpuru ma oxidizing na mbenata ọnọdụ.Mgbe a na-agwọ okpomọkụ ngwọta, alloy N155 alloy nwere ihe dị ka nguzogide nitric acid dị ka igwe anaghị agba nchara.Ọ nwere nguzogide dị mma karịa igwe anaghị agba nchara na ngwọta na-adịghị ike nke hydrochloric acid.Ọ na-eguzogide mkpokọta sulfuric acid niile na ụlọ okpomọkụ.Enwere ike ịmegharị alloy ahụ, kpụọ ya na oyi-atụ site na usoro omenala.

The alloy nwere ike welded site dị iche iche arc na iguzogide ịgbado ọkụ Filiks.Alloy a dị dị ka mpempe akwụkwọ, warara, efere, waya, electrodes mkpuchi, ngwaahịa billet na nkedo nwere ezi uche na itinye ego.

Ọ dịkwa n'ụdị nke re-agbaze ngwaahịa na kemịkalụ akwadoro.A na-ebufe ọtụtụ ụdị arụ ọrụ nke n155 alloy na ọnọdụ a na-agwọ okpomọkụ iji mesie njirimara kacha mma.A na-enye mpempe akwụkwọ ọgwụgwọ ọgwụgwọ okpomọkụ nke 2150 ° F, maka oge dabere na oke akụkụ, ikuku dị ngwa ngwa ma ọ bụ nkwụsị mmiri na-esote.Ogwe mmanya na efere (1/4 inch na arọ) na-abụkarị okpomoku ngwọta na-ekpo ọkụ na 2150ºF na-esote mmiri menyụọ.

Alloy N155 tara ahụhụ site na mediocre oxidation resistance, a ọchịchọ nke okpomọkụ emetụta mpaghara cracking n'oge ịgbado ọkụ, na a dịtụ wider gbasasịrị gbalaga nke n'ibu Njirimara.

Sekonic Metals Technology Co., Ltd ISO 9001 ụlọ ọrụ ruru eru ọkachamara na mmepụta nke High okpomọkụ Alloys na Anti-corrosion Alloys dị ka Titanium Alloys, Precsion Alloys (Invar 36, Kovar 4J29, Soft Magnetic Alloys,)Hastelloy Alloys, Haynes Alloys, Monel Alloys. , Inconel Alloys, Incoloy Alloys Coblat Alloys (Haynes 25, Alloy 188, Stellite Alloys) ect Kemgbe1996.mgbe enwetara nnukwu ihe ịga nke ọma na ahịa China, anyị na-agbatị azụmahịa anyị n'ụwa niile ebe ọ bụ na 2000A na-eme ngwaahịa niile dị ka ụkpụrụ dị mkpa ma nyochaa nke ọma tupu izipu ụlọ ọrụ anyị.Dị ka RoHS na IS09001: 2008 ọkọlọtọ, anyị ngwaahịa na-ọnọ na mmanya, mkpanaka, waya, efere, warara, mpempe akwụkwọ, ọkpọkọ ano tube, na ndị ọzọ shapes nke a na-eji n'ọtụtụ ubi, dị ka ụgbọ elu & aerospace, metallurgy, ígwè ọrụ. , Electronics chemicals, energy, high energy, etc. anyị ụlọ ọrụ ga-mgbe niile na-adabere na mmụọ nsọ: "àgwà mbụ, ahịa mbụ" na-eje ozi maka anụ ụlọ na esenidụt ọrụ.